5 Best Concrete Sealers for Garages and Driveways

Concrete floors may be slowly gaining popularity in homes, but they’ve been a staple for both garages and outdoor use for a long time. Over time, these surfaces need maintenance, and you can’t go wrong with as good sealer.

Each of the following products are potentially the best concrete sealer for their type.

Our 5 Favorite Concrete Sealers

| Product | Type | Sheen | Size | Coverage (per gal) |

|---|---|---|---|---|

| Concrete Sealers USA PS101 | Penetrating | Clear | 1 or 5 gal | 250-450 sq ft |

| EnduraSeal 7747509 Sealer | Surface | Semi-Gloss | 5 gal | 150-300 sq ft |

| ToughCrete Concrete Sealer | Penetrating | Clear | 1 gal | 150-250 sq ft |

| Ghostshield Lithi-Tek LS 9500 | Penetrating | Clear | 1 gal | up to 500 sq ft |

| DryWay 205 Concrete Sealer | Penetrating | Clear | 5 gal | 150-200 sq ft |

Concrete Sealer Reviews

There’s a wide variety of sealers available out there, and you can generally find a few brands at big box home improvement stores like Home Depot (if in a time crunch), smaller independent dealers, or online retailers like Amazon (good price and selection).

#1 – Concrete Sealers USA PS101 Siliconate Sealer

When you need a good penetrating concrete sealer for unsealed and uncolored smooth troweled concrete surfaces, you can’t do much better than Concrete Sealers USA’s PS101. This professional grade sealer penetrates into porous substrates of hand or machine troweled concrete (ex. garage floor, shop floor, warehouse floor, etc.) and can be used for both residential and commercial applications.

When you need a good penetrating concrete sealer for unsealed and uncolored smooth troweled concrete surfaces, you can’t do much better than Concrete Sealers USA’s PS101. This professional grade sealer penetrates into porous substrates of hand or machine troweled concrete (ex. garage floor, shop floor, warehouse floor, etc.) and can be used for both residential and commercial applications.

PS101 works by penetrating into the pores and capillaries of a porous concrete surface and through a chemical reaction within the surface creates a cross linked methyl-silicone internal protective membrane. Because the membrane is within the surface and does not form a film or coating on the surface, it doesn’t always eliminate all issues one might experience with their concrete surface but it will almost always significantly reduce or control most issues.

The sealer will also wear better, last longer, and never be susceptible to scratching, chipping, peeling, or delaminating like a lot of topical sealers/ coatings. While the 5-gallon container is the best value, PS101 is also available in a 1-gallon jug for small jobs.

The issues that the PS101 can help limit, manage, or control are common problems associated with freeze/thaw damage, scaling and spalling, and deicing chemicals and salts. The PS101 sealer can also help decrease efflorescence, retard mold and mildew growth, limit dirt buildup and deep staining, and generally makes a surface much easier to clean and maintain. The sealer normally doesn’t change the appearance of a surface once applied.

The PS101 is not by itself a “silver bullet” solution but it maybe all you need when used along with a hard troweled floor and good long term care and maintenance. The combination of the three (PS101 sealer, smooth floor, and good maintenance) generally results in a more practical, reliable, cost effective, easily maintained, durable, and longer lasting solution than more expensive topical coating systems (ie: urethanes, epoxies, polyaspartics, etc.) as well as less expensive acrylic sealers or garage floor paints that usually peel, chip, delaminate within a short period of time.

In areas of the country that experience extremely harsh winters, you may also want to consider complementing the PS101 with a good garage containment mat to further aid in the protection and clean up of your surface resulting from snow, ice, deicing chemicals, road grit, etc.

Application of this sealer is quick and easiest with a low pressure garden sprayer along with a broom, roller, or microfiber pad to evenly distribute product as well as disperse any excesses within 10 minutes. As with other sealers, you’ll want to make sure the surface is clean (ie. no dust, dirt, oil, curing agents, previous sealers/ coatings, or other surface contaminants) and completely dry. Using a high quality concrete cleaner is crucial.

Expect one gallon to cover about 250-450 sq. ft on a smooth troweled floor. Since it is water based, it should be dry to the touch in 1-3 hours and safe to walk on in about 6-12 hours. A full dry/ cure is typically 24 hours and surface should not be exposed to any water during this period.

While the PS101 may also help to a degree with abrasion resistance and surface wear, resisting harmful effects caused by water, moisture, salts, dirt, mold/ mildew is its primary purpose. If you want to add surface densifying/hardening properties, be sure to also check out the company’s PS104 lithium silicate densifying sealer which also contains Siliconate as an additive so that it also possesses some of the same performance characteristics as the PS101.

For those customers looking for benefits similar to the PS101 but instead have broom finished surfaces (ex. driveways, sidewalks, patios, etc.) or concrete block, Concrete Sealers USA offers the PS102 Siliconate Sealer. The PS102 is based on the same Siliconate chemistry as the PS101 but it also contains a proprietary polymer additive that allows for a better seal on rougher, more porous surfaces in addition to providing better freeze/thaw protection in harsh climates. The product is limited to use on broom finished concrete and concrete block and cannot be used on any other surface types.

Users are quick to point out how well water and other water based fluids simply bead, sheet, or are significantly restricted from absorbing into the surface after the sealer has been applied. And, if you catch a motor oil spill reasonably quickly, with a good cleaner and a little scrubbing, even motor oil doesn’t leave a stain or at least is significantly reduced.

Customer service is also where Concrete Sealers USA really shines which is something other companies can learn a thing or two from. They encourage all customers to call them prior to purchase and/ or use to ensure customers select the right product for their project and to also provide them with helpful tips for successful application.

An issue a few users experienced is a whiteish residue appearing on the surface after application. This is simply due to too much sealer being applied, not dispersing any and all excesses in 10 minutes, or a second coat unnecessarily added. Since this is a penetrating sealer, it should be applied applied to the point of rejection and be fully absorbed into a surface. Excess will simply remain on top of the surface where it then dries and can leave behind a white residue . If this accidentally happens, you can simply pressure wash the surface to get rid of the residue or allow it to dissipate on its own over time.

>> Check price at ConcreteSealersUSA.com <<

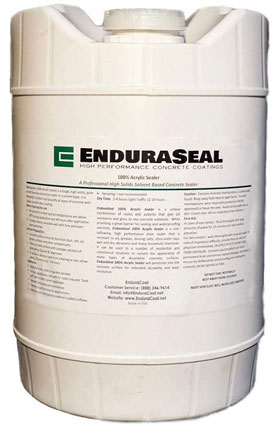

#2 – EnduraSeal 7747509 Concrete Sealer

This high performance, semi-gloss solvent sealer gives your substrate floor a shiny “wet” appearance. Made of pure acrylic, this sealer won’t yellow with age and remains highly durable without the associated cost found in other sealers. Two thin coats are recommended, and each gallon of the 5-gallon bucket will cover approximately 150 to 300 square feet.

This high performance, semi-gloss solvent sealer gives your substrate floor a shiny “wet” appearance. Made of pure acrylic, this sealer won’t yellow with age and remains highly durable without the associated cost found in other sealers. Two thin coats are recommended, and each gallon of the 5-gallon bucket will cover approximately 150 to 300 square feet.

Those who have purchased this sealer tend to be very enthusiastic about it. They stress proper preparation of the surface, but have reported excellent results using a sprayer or roller. In addition, they note that stained or painted surfaces sometimes look better than they originally did, thanks to the mild sheen from the sealer.

Related: 5 Best Paints for Garage Walls

Some consumers have had problems with discoloration after the concrete surface was exposed to direct sunlight for a prolonged period of time. Unlike the yellowing common in sealers, these users reported that this product would cloud over and turn a milky white.

Some consumers have had problems with discoloration after the concrete surface was exposed to direct sunlight for a prolonged period of time. Unlike the yellowing common in sealers, these users reported that this product would cloud over and turn a milky white.

The reason why this happened is unknown, so we recommend when using this as a concrete driveway sealer to test first in a small area exposed to direct sunlight.

>> Check current price <<

#3 – Quest Chemicals ToughCrete Concrete Sealer

This penetrating sealer is perfect for outdoor use, although it also makes an excellent garage floor sealer. As a siloxane product, it is eco-friendly and will protect against deterioration, salt damage, and water.

This penetrating sealer is perfect for outdoor use, although it also makes an excellent garage floor sealer. As a siloxane product, it is eco-friendly and will protect against deterioration, salt damage, and water.

Before using on any patterned or colored surface, you should remove any existing protective coat to allow for better penetration. With a satisfaction warranty of ten years, the mixture is water based and each gallon dilutes on a 1:2 ratio.

Users have had a lot of success with this product. Some have used it full strength, others diluted, and a few have done both based upon how heavy a particular area gets abused. In all cases, they have reported excellent results.

While nobody has reported if it lasts the full ten years, it has certainly held up for users more than one year with no loss of performance.

No product is perfect, and ToughCrete isn’t an exception. On rare occasion, a user will still experience leaf stains. The reason for this is unknown and may have to do with how the product was applied or be related to the intensity of weather in that location. Whatever the cause, Quest Chemicals has stood by their warranty, making this product a very low financial risk to try.

>> Check current price <<

#4 – Ghostshield Lithi-Tek LS 9500 Concrete Sealer

When you want a garage or patio sealer, the industrial strength power of the LS 9500 blows away the competition. This sealer was designed strictly for solid concrete substrates and will not work on concrete block or polished surfaces

When you want a garage or patio sealer, the industrial strength power of the LS 9500 blows away the competition. This sealer was designed strictly for solid concrete substrates and will not work on concrete block or polished surfaces

Surfaces coated in this sealer not only have the usual waterproofing and abrasion resistance, but suffer less from ASR, hydrostatic pressure, moisture intrusion, and water vapor transmission. The concrete itself is strengthened by up to 50 percent, and up to 1,000 square feet of concrete per coat can be covered once the sealer concentrate has been mixed with water in a 1:4 ratio.

See Also: How to Make Plywood Waterproof

Users have been pleasantly surprised by the effects of this sealer. The concrete clear coat goes on well and penetrates deep. As a result, they have noted that water beads on the surface after a couple days of curing.

Despite following instructions precisely, some users have had negative results. These vary from efflorescence to stains. Using this product on a polished floor will result in the sealer failing and may lead to water damage.

>> Check current price <<

#5 – RadonSeal DryWay 205 Concrete Sealer

Perfect for external surfaces, this penetrating sealer will protect concrete and masonry for several years. It forms a resistant 1/2 inch deep barrier against deterioration, mold, spills, and water penetration. It will also stand up well to direct sunlight, and resists heat, oxidation, and UV-rays.

Perfect for external surfaces, this penetrating sealer will protect concrete and masonry for several years. It forms a resistant 1/2 inch deep barrier against deterioration, mold, spills, and water penetration. It will also stand up well to direct sunlight, and resists heat, oxidation, and UV-rays.

Water and other liquids bead and are easily wiped away from the surface. One five gallon bucket will cover as much as 1,000 square feet of poured concrete, although other surfaces will require more to properly coat.

Consumers love how well the water beads on this sealer. Many with longer driveways have had to order a second bucket and have noticed a huge difference between the coated and uncoated sections after a rain. They recommend using a sprayer for the most efficient application.

This product has a much shorter lifespan in harsh climates, with some users reporting they have to reapply annually. There have also been some reports of leaf stains in the autumn. Older driveways that have never been treated can also require more sealer, so be ready to purchase an extra bucket in such cases.

>> Check current price <<

FAQs

Once upon a time (as recently as 50 years ago), the concept of concrete sealers was unheard of to the average homeowner. Nowadays, with the increased use of deicing chemicals and harsher weather conditions, sealers have become almost a necessity. The following questions are often asked by first-time buyers and will help you with choosing and using a sealer.

What does a concrete floor sealer do?

As the name implies, a concrete floor sealer will form a protective layer over your concrete floor or driveway. Not only can it protect against abrasion, stains, and even pet urine, but it can also enhance the color of your floor or give it a sheen, if a gloss is used.

There are two major types of sealer, and you can buy sealers in several different compounds, such as acrylic and epoxy. Surface sealers coat the surface in a protective layer. However, penetrating sealers will also bond with the concrete, adding additional protection against water saturation and the effects of deicing chemicals.

For this reason, the latter works best for driveways or other external surfaces, while the former is most often used on interior floors.

See Also: How Penetrating Sealers Work (the Science)

How do you apply concrete floor sealer?

Resealing your concrete surface is a simple process, but involves numerous steps. Both indoor and outdoor concrete floors have similar steps and it’s a bit more complicated than sealing a granite countertop for example.

Be sure to follow any additional directions included with your chosen sealer. You may apply concrete sealer using a roller or a sprayer.

You will need: scrub brush, mop, putty knife, degreaser, concrete filler (for regular concrete surfaces), and sealer.

- Remove everything from the surface. Remember, sealers only work if you apply them to the entire surface.

- Remove anything along the edges, such as baseboards or overhanging grass and open windows, if working indoors.

- Thoroughly sweep the surface to remove dust and other particles. Optionally, you may want to sand the concrete floor to smooth it out or create a new finish.

- Using a degreaser, remove any traces of grease or oil on your garage floor or driveway. You may have to scrub out tough stains.

- Mop the floor to remove any last traces of dust or chemicals. Allow the surface to fully dry.

- Apply concrete filler to any cracks or other damage as directed on the product, smoothing over with a putty knife. Give the filler several hours to cure.

- Add a small amount of sealer into a paint tray (if using a roller brush) or sprayer.

- Apply the sealer in a thin, even coat across the entire concrete surface. A regular brush is a good way to apply sealer along the edges before tackling the middle of the floor.

- Allow the coat up to 24 hours to dry. Using fans may help cut the time to as little as 12 hours.

- Apply additional coats as required for your sealer.

See Also: 27 Garage Wall Paint Ideas

What’s the difference between Concrete Sealer and Epoxy?

On the surface, epoxy functions much like an acrylic, polyurethane, or siloxane sealer. However, an epoxy sealant is actually a type of surface coating. As epoxy doesn’t penetrate, let’s compare it to acrylic, the most popular surface concrete sealer.

Acrylic

As is typical with most surface sealers, acrylic may be either solvent or water based. They’re available in matte, clear, or gloss finishes and are applied in two thin coats. While perfect for more delicate stamped surfaces, acrylic isn’t as durable as penetrating sealers, so it will need recoated more often.

It dries quickly and cures in about a day. Solvent-based acrylics tend to be better for driveways and also enhance colored surfaces a bit better than the water based version. As many acrylic sealers offer UV protection, they are a good choice for external surfaces.

Epoxy

More commonly found in high-traffic areas, industrial settings, and places prone to chemicals or abrasion; an epoxy bonds with the concrete surface, making it extremely durable. Epoxy usually leaves a gloss finish, and is available in both clear and colored form.

It forms a thick surface coating on the garage floor that is harder than acrylic, although its non-porous makeup can leave existing water trapped under the surface. It also yellows when exposed to too much sun, making it an interior only solution.

Acrylic vs Epoxy Comparison Chart

| Acrylic | Epoxy | |

|---|---|---|

| Location | Indoor or Outdoor | Indoor |

| Durability | Moderate | High |

| Surfaces | Most | Poured |

| Preparation | Average | Major |

| Application | Brush, Roller or Spray | Brush or Roller |

| Dry Time | 1 Hour to touch, 24 hours to cure | Sets fast, dries slow |